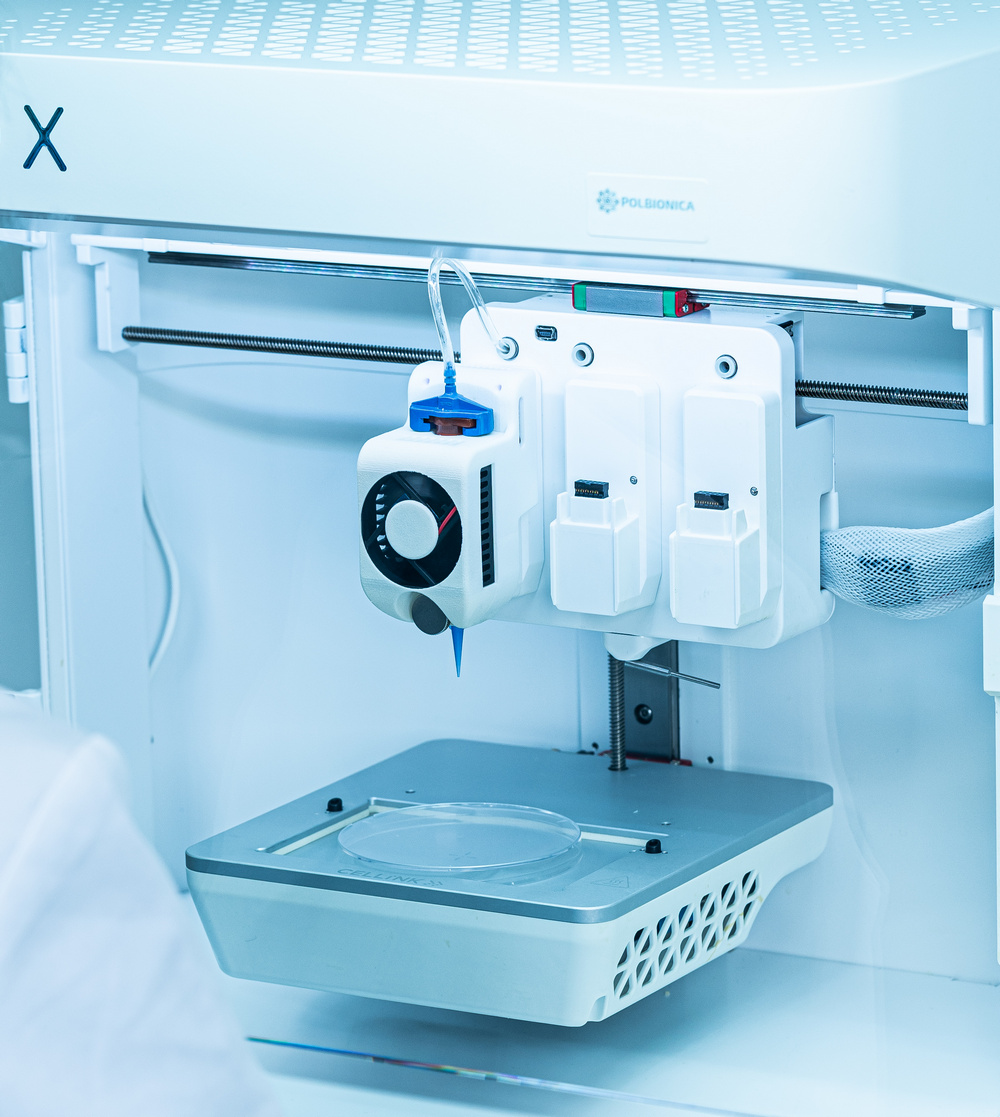

3D bioprinting has become an extremely versatile tool in the fields of biological sciences and regenerative medicine over the past decade.

It is used in the production of bone defect implants, and increasingly in the construction of functional organs such as the pancreas, lungs, liver, heart, and skin. Moreover, tissue engineering is utilized in biotechnology research, in the creation of disease models for cancer, and in screening compounds in drug production. To achieve the desired tissue construct, a range of cells, methods, and materials can be used in 3D bioprinting, depending on the nature of the printed object.

The bioinks used in 3D bioprinting exhibit a very wide spectrum of biophysical characteristics: viscosity, printability, and degradation. Additionally, they must provide favorable conditions that allow for cell embedding and differentiation, without cytotoxicity.